Carton handling plays an essential role in many industries where products are transported, sorted, stored and packaged, such as the food industry, logistics, etc. It is crucial to adopt the right solutions to ensure a smooth flow and optimal efficiency.

Your packages or boxes can be transported by several types of industrial conveyors. The choice will vary depending on the dimensions, weight, products contained, speed or conditions of use.

Voici des solutions utilisables pour cette application :

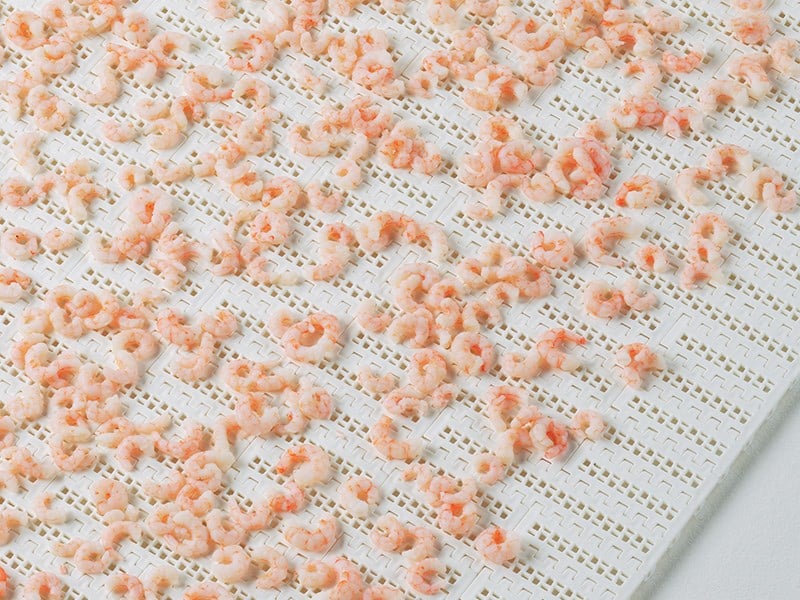

Modular Belt Conveyor

These conveyors are generally used for food products, packaged products, etc. You can easily transport your packages on your line using this type of industrial conveyor.

The Flextoo conveyor is also designed for environments containing cardboard dust, but it is also possible to use other industrial conveyors for this purpose.

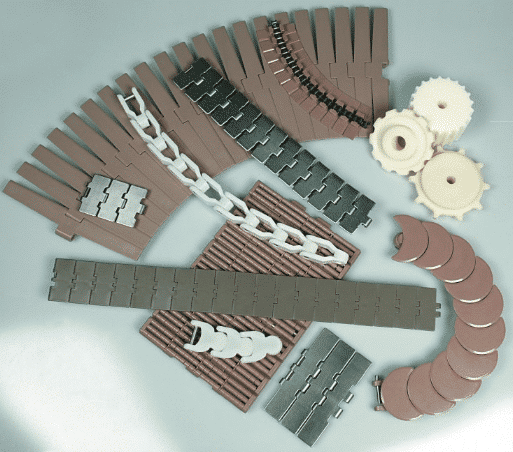

Chain conveyors

These industrial conveyors are frequently used for unitary products but can also convey boxes.

The Robur conveyor is a good example of transporting boxes with heavy load, accumulation and presence of dust.

Complementary components

Carton management involves specific conditions and functions such as the management of accumulations and large loads.

It may also be necessary to make diversions, sorting or 90° transfers of packages or boxes.

Chains and belts for industrial conveyors

The boxes can be transported with different belts compatible with these conditions of use (Uni-Chains belts and Scanbelt belts) and chains for industrial conveyors.

Belts and chains with accumulation rollers or oriented rollers can solve certain problems.

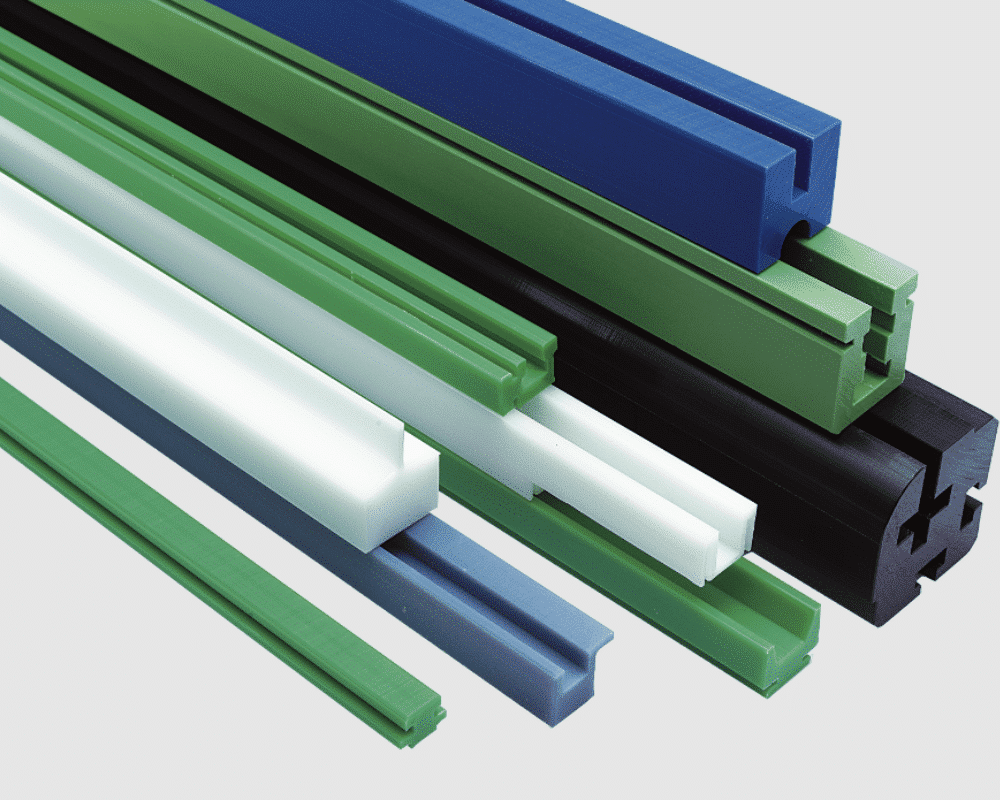

Sliding profiles and guidance

These industrial conveyors are frequently used for unitary products but can also convey boxes.

The Robur conveyor is a good example of transporting boxes with heavy load, accumulation and presence of dust.

Carton management involves specific conditions and functions such as the management of accumulations and large loads.

It may also be necessary to make diversions, sorting or 90° transfers of packages or boxes.

Things to take into account

When it comes to choosing the best carton handling solution, there are several factors to consider.

The strength of the conveyor, its ability to operate in dusty environments, its modularity and ease of use are all important aspects to consider. It is also essential to choose the right components such as modular belts or belts, chains and accessories, which help ensure safe and accurate delivery of cartons through the conveyor line.

Our expertise allows us to understand the challenges you face and offer you tailor-made solutions that meet your specific needs in order to increase your productivity, or improve the security of your operations.