Faber

Machined plastic screws

Screws, and machined plastic parts in general, can be used for many different purposes. Customized systems can be used for specific operations, such as stacking or unstacking products. This solution is achieved using variable-pitch screws.

Screws can be used not only for transport, but also for product handling, which is essential to ensure the smooth running of a packaging line.

Screw characteristics

We can machine these parts in any material of your choice, including:

PA6, PE, PEEK, PETP, PETP TX, POM, PP, PTFE, PVC, PVDF and aluminium.

We produce functional screws according to the various parameters of the specifications (dimensions, shapes and materials of the products, desired functions and production rates, mechanical and dimensional requirements of the working environment).

Applications for machined plastic screws

Spacing screw

The most common function of screws is spacing. It positions products at a regular distance from each other and in synchronisation with the following equipment on the production line.

These screws are very often used with star wheels and guides on machines used to package vials or bottles.

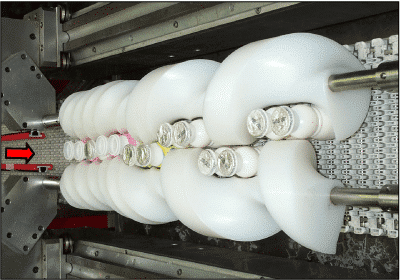

Rotating screw

Another essential function of screw is rotating. In this case, we use a set of 2 opposing screws to control the orientation and positioning of the products leaving the unit.

Grouping or distribution screw:

Screws can also be used to group products from 2 lanes into a single lane or, conversely, to distribute products from one lane into 2 parallel lanes. These screws can also be used to create 2, 3 or even 4 products.

For fragile products or products with complex or unstable shapes, we use pucks into which the products are placed. They can then be manipulated by screws to perform all the functions possible with single products.

Specific screws:

Other more specific functions are available, such as tilting the product forwards or backwards, or laying it on its side. Plastic lid unstacking screws allow products to be distributed one by one, this time very often used in a vertical position.

Other functions, such as screws with STOP, enable products to be positioned and stopped briefly in the screw(s), so that an operation can be carried out without stopping the rotation of the screw(s).

Our engineering department is at your disposal to discuss all the possibilities with you in order to manage your needs as effectively as possible and to study the feasibility of the project.

Our design office is at your disposal to discuss all the possibilities with you in order to manage your needs as effectively as possible and to study the feasibility of the project.

A question?

Feel free to call on us to make you a quotation or to arrange for an expert assistance to help you achieve your projects