Faber

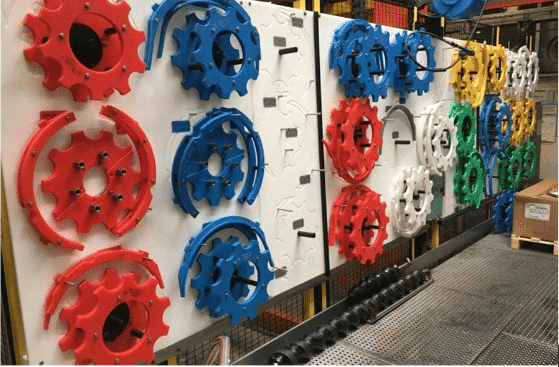

Plastic starwheels and guides

Our plastic starwheels and guides are custom-machined parts designed to meet your specific requirements in the field of liquid packaging.

Combined with the alignment screws, the stars are used to manage the supply of vials or bottles at the infeed of a packaging machine, while the guides ensure that the products are held in the correct orientation and position during transport.

Description of plastic star wheels and guides for conveyors

These solutions are suitable for all industries involved in packaging liquids, such as the pharmaceutical and food sectors, as well as household products and industrial oils.

The starwheels enable products to be fed into a packaging machine and held there during all the operations it performs on vials, bottles or cans: rinsing, filling, capping, corking or labelling.

Characteristics of guides and starwheels for industrial conveyors

The guides

To accompany our starwheels, we offer either standard guides in various materials, with or without metal frames, fitted with ball-bearing rollers or brushes, or machined guides specific to the starwheels.

The latter can be designed to ease format changeovers thanks to the ROTOBLOC quick assembly/disassembly system, offering flexibility and reduced production downtime.

Practical uses

Our stars can be used for a wide range of applications, enabling your products to be turned so that they can undergo the desired operations in series.

The stars are available in different sizes and colours for different formats.

ROTOBLOC/CLICNET systems

We offer advanced systems and innovations such as the ROTOBLOC system, which enables stars and guides to be changed quickly when switching production campaigns to a different product format.

The CLICNET system is a locking/unlocking system for tooling without requiring any retention zone to ease cleaning.

OV-Protect / OMS systems

Faber has designed the OV-Protect process to protect fragile products from surface scratches and polishing.

Finally, the OMS system enables several product formats to be processed using the same equipment (stars and guides), which contributes to optimising line downtime between 2 production runs.

Our design office is at your disposal to discuss all the possibilities with you in order to best manage your needs and study the feasibility of the project.

Other plastic tools such as turning sleeves or pucks are available.

A question?

Feel free to call on us to make you a quotation or to arrange for an expert assistance to help you achieve your projects