Faber

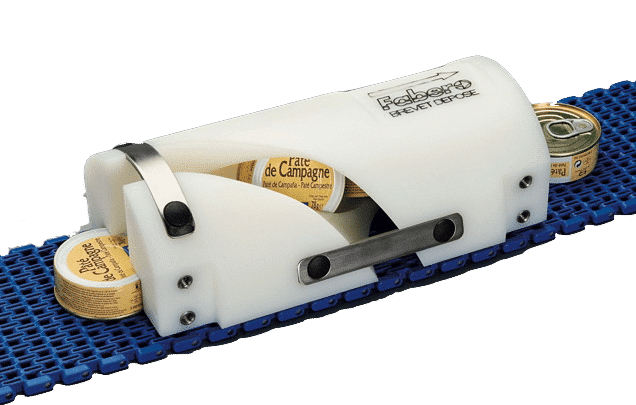

Turning units for packaging line

Plastic machining allows the custom manufacturing of turning sleeves. These sleeves allow products to be turned over with angles of 90°, 180°, 360°, or even with a precise angle depending on the needs.

The smooth inner surface protects your products, and the unit accompanies the product as it rotates, eliminating the need for a guide.

Description of turning units for packaging

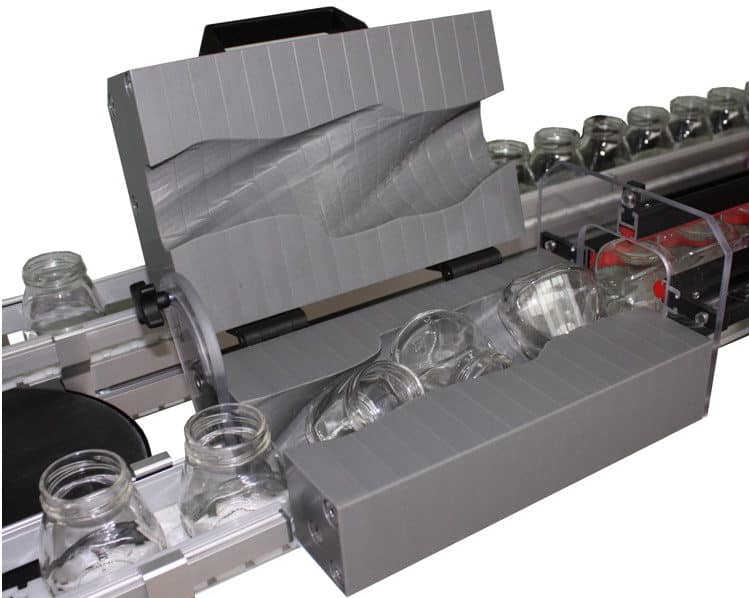

They are useful for removing impurities from products, by turning bottles through 180° to blow them out and/or vacuum up impurities. Turning units can also be used to sterilise filled and sealed bottles.

Characteristics of turning units

Custom-made

Turning units are custom-made to meet the specific needs of each application.

They are designed according to the shape, size and turning angle required for the products to be handled.

They can be positioned between 2 conveyors or placed on the chain when required.

Multi-purpose applications:

Turning units are often used in the pharmaceutical, cosmetics, food and other industries where products need to be turned to clean containers.

But it is also possible to turn cylindrical mechanical parts to meet the needs of the manufacturing process.

Possible opening:

Turning units can be designed with a 2-part hinged opening to facilitate cleaning and maintenance.

Compatibility with other equipment:

Turning units can be combined with other equipment such as blowing/rinsing machines or robots for specific operations. They can be perfectly integrated into your packaging or production lines.

Other plastic products are used to handle bottles, such as plastic bottle-holding pucks

In addition, the turning units can lay the products down to position them so that they can be picked up by a robot during cartoning or boxing operations.

These elements can operate without any external energy input thanks to the thrust exerted by the accumulation of products, often using the gravity force to rotate the products inside.

However, it is possible to add a banderoller at the unit infeed to create sufficient thrust for the products to move forward.

Other plastic products are used to handle bottles, such as plastic bottle-holding pucks

A question?

Feel free to call on us to make you a quotation or to arrange for an expert assistance to help you achieve your projects