Faber

Industrial Conveyor Chains

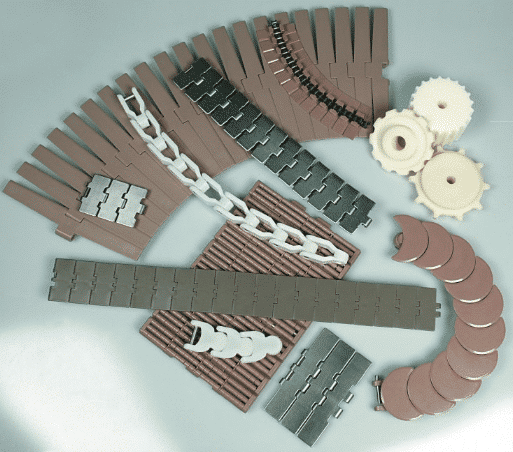

Our chain conveyors can be equipped with various types of chains, commonly used in the food, pharmaceutical, logistics, and automotive sectors.

These chains, made of different plastics or metals, are designed to withstand significant traction forces.

The industrial Conveyor Chains

Our chains for industrial conveyors are designed to transport a multitude of products of different shapes, such as vials, bottles, plastic/metal/glass/cardboard packaging, boxes, mechanical parts, etc.

Each type of chain has specific features adapted to different needs.

They serve as alternatives to industrial conveyor belts, as well as Uni and Scanbelt modular belts for narrower widths.

Characteristics of chains for industrial conveyors

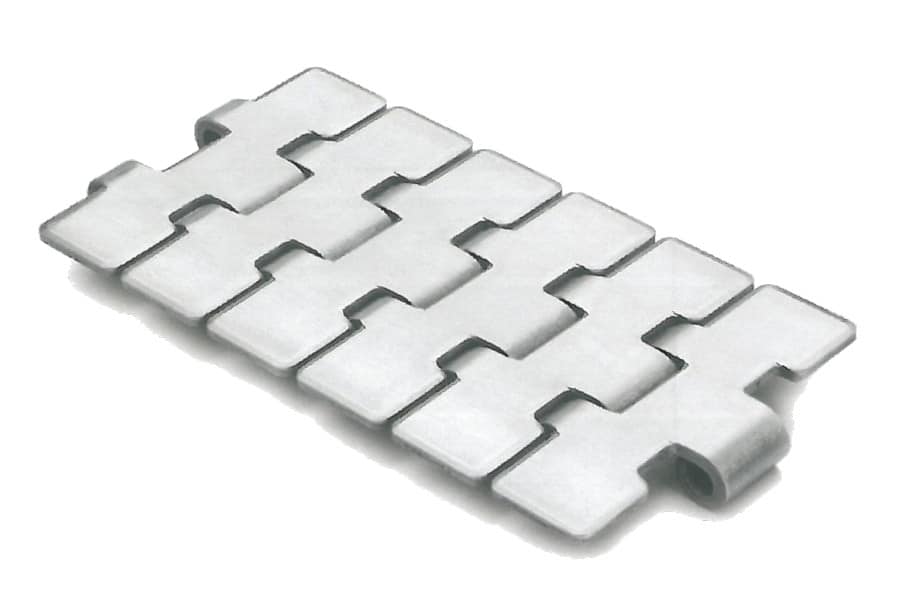

Straight Chains

Available in steel, stainless steel and plastic, they are suitable for various industrial applications, offering resistance to tensile stress and the ability to transport different products.

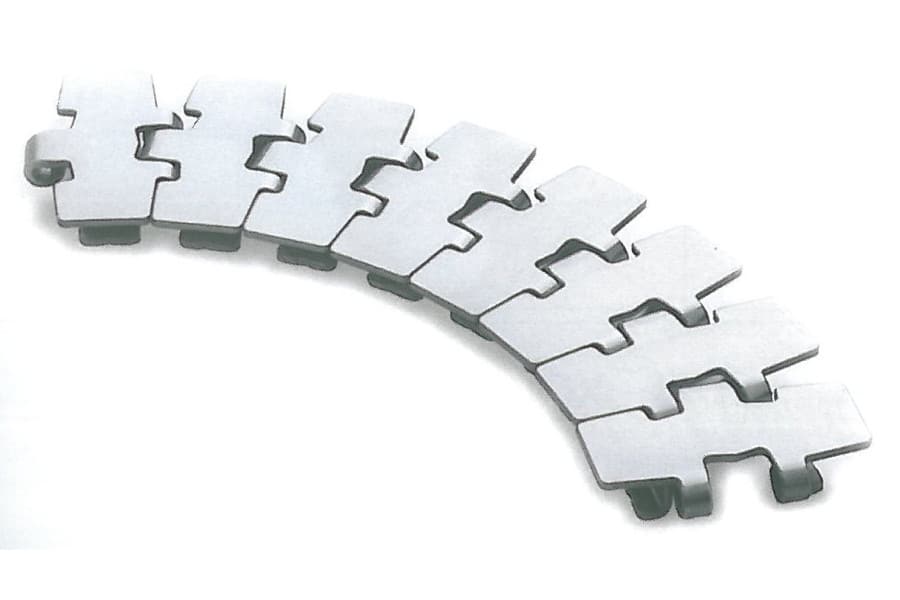

Flex chains

Made of metal or plastic, these conveyor chains are flexible and accept a radius of curvature.

They are used in standard conveyors, elevators and accumulators for the transport of various products. There are a large number of different variations.

Monoplan chains

Light but robust, these plastic chains are ideal for handling boxes/crates.

They withstand heavy workloads, can be used in straight or curved applications and are easy to clean.

Biplan chains

These plastic chains are suitable for transporting various products, particularly in breweries/dairies.

They offer high strength, quiet operation, easy cleaning and are available in different widths.

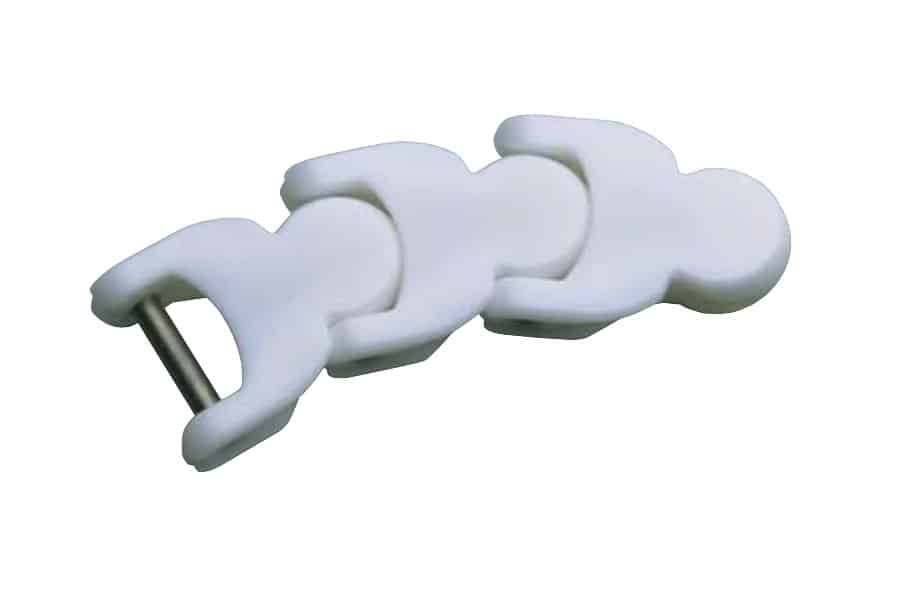

Biflex chains

These chains are available in plastic or metal material. The pitch of these chains is generally 25.4 mm or 38.1 mm.

These chains, also called paddle chains, can follow straight or curved directions.

Sprockets for chains

We supply the sprockets associated with these chains. Each chain model has several sprocket sizes depending on the number of teeth.

They are made of cast iron, steel, stainless steel or plastic and have different characteristics.

Depending on the products transported, as well as the type of environment in which your lines are located, you can opt for different sprockets with bore and keying on demand and even 2-part sprockets to facilitate maintenance on your conveyors.

You will be able to personalize your conveyors a little more according to your needs by choosing the feet, as well as the guides of your industrial conveyors.

A question?

Feel free to call on us to make you a quotation or to arrange for an expert assistance to help you achieve your projects