The machining of plastic parts makes it possible to produce single parts in small or medium series without tooling costs.

It is a manufacturing process by removing material, until the expected shape and dimensions are achieved.

The technical advantages of plastic parts

Plastic parts are much lighter than metal parts, which makes them very useful for industries where the weight of structures is a key factor.

The mechanical resistance is greater than 3D plastic printed parts.

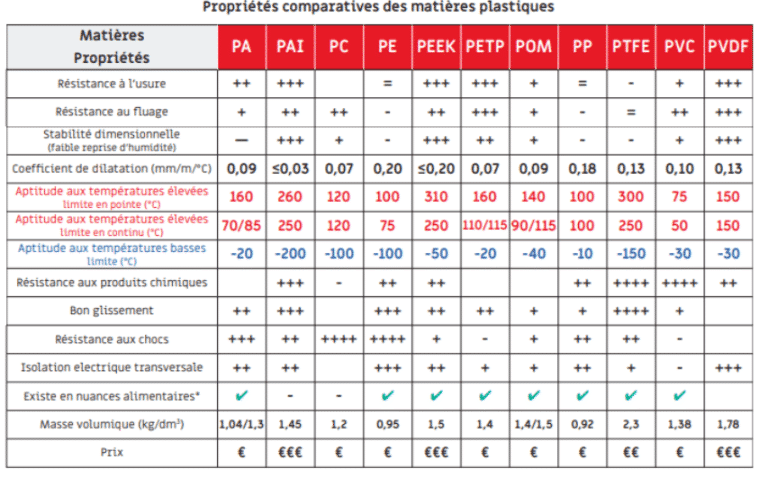

Many materials exist to suit all needs. Conductive or insulating materials, resistant to abrasion or temperature, are all possibilities for solving a number of problems.

Manufacturing costs for plastic parts are lower than for metal parts particularly in the agri-food sector where it is essential to respect the standards in force.

Systems designed with plastic parts are less noisy than those designed with metal parts. Working conditions for staff are therefore more pleasant and can in certain cases avoid the need to wear individual hearing protection.

Plastic is corrosion resistant and some grades even resist chemicals or oils.

The sliding coefficients of plastics are better than those of metals, which makes it possible to reduce the energy consumption of the systems in the parts that are integrated.

We can machine different types of technical plastic parts:

- Plastic parts turned and/or milled according to plan

- Customized standard sliding profiles

- Technical plastic parts specific to packaging (screws, tools, turning sleeves)

- Plastic wear parts for cardboard boxes, etc.

We can also engrave your references on the machined plastic parts on request.

Which plastic to choose for plastic parts?

We provide you with different qualities and grades of plastic materials for machining parts. Each material is adapted to very specific technical constraints.